- Home

- Capabilities

- Manufacturing

As an agricultural machinery solution provider, YTO has made a breakthrough in power shifting, CVT and autonomous driving technology to further improve performance of tractors. Now YTO’s tractors are widely used to deep tillage, plowing, harrowing, rotary tillage, planting and plant protection on a variety of terrains.

YTO always pursues higher goals. We will improve the intelligent level of autonomous driving, precision agriculture and agricultural machinery information service platform to shape the future as an agricultural machinery manufacturer, service provider and information exchange platform.

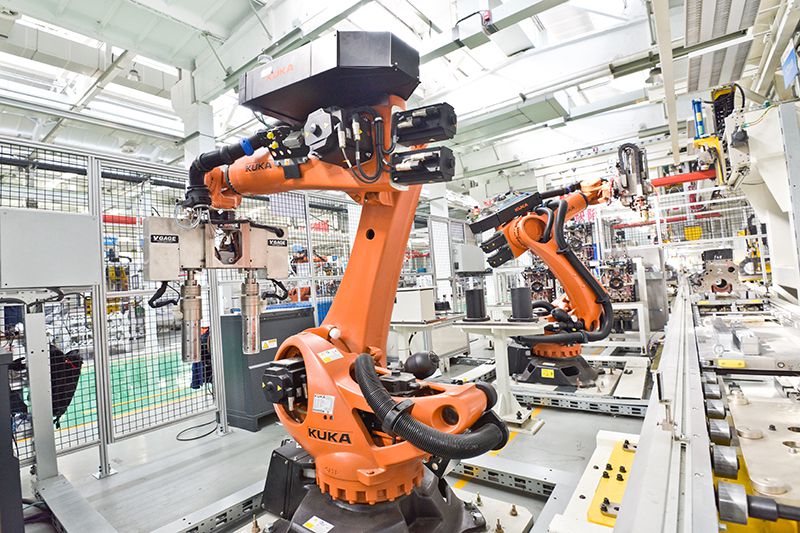

4 projects of YTO were set as Intelligent Manufacturing Samples by the Ministry of Industry and Information Technology of China

Digital factory of smart cabs of modern agricultural equipment

Digital factory of smart cabs of modern agricultural equipment Smart cab production lines in Fulaige company under the YTO group

Smart cab production lines in Fulaige company under the YTO group

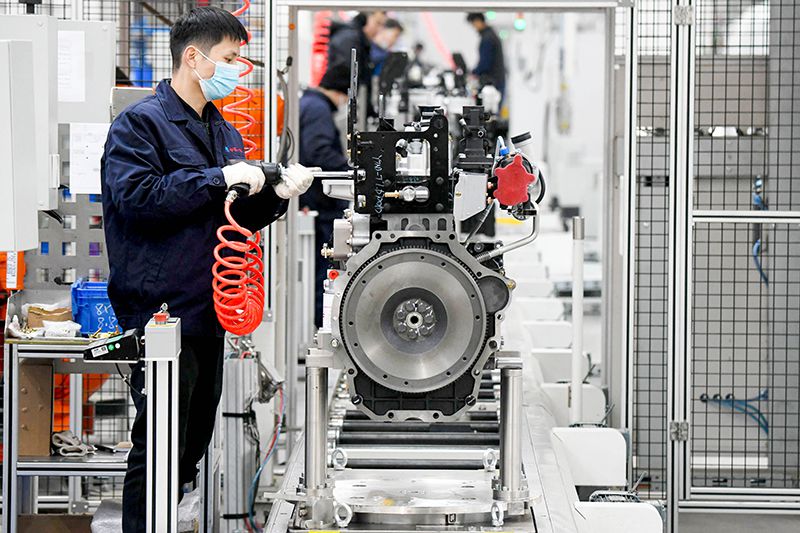

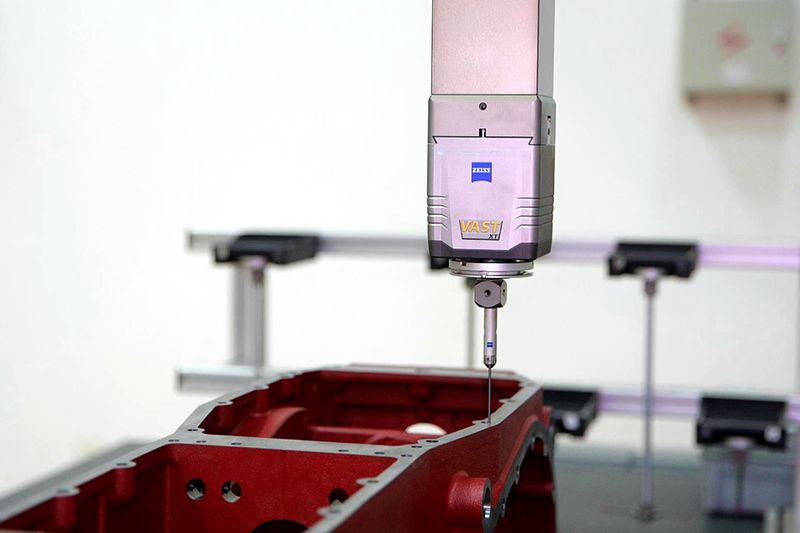

YTO boasts the advanced intelligent manufacturing capacity and the key part manufacturing technology in China’s agricultural machinery industry.

YTO has a complete production chain of tractors, from key parts to agricultural vehicles, from production to assembly, and we can produce agricultural machinery based on the international standards or clients’ needs to fit various requirements and enter different countries.

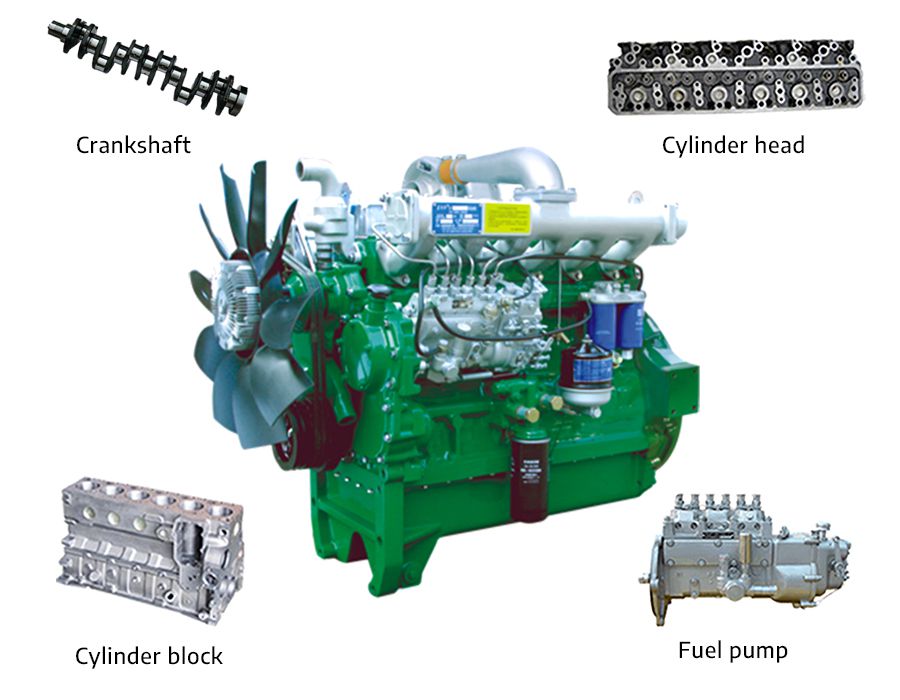

- Diesel engine manufacturing

- Vehicle exterior manufacturing

- Chassis manufacturing

- Drivetrain axle manufacturing

- Key part manufacturing

- Crankshaft production

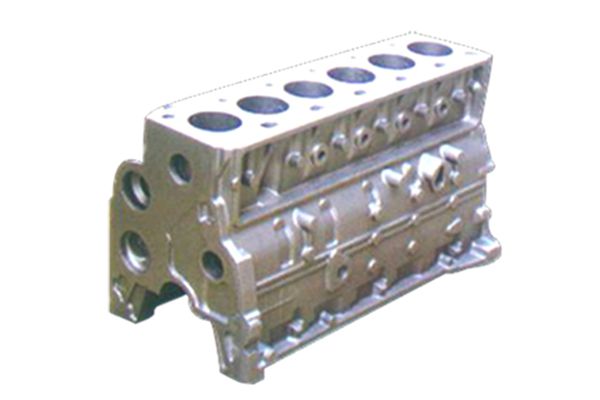

- Cylinder block production

- Cylinder head production

- Fuel pump production

Chassis manufacturing

Rigid connection of chassis assembly

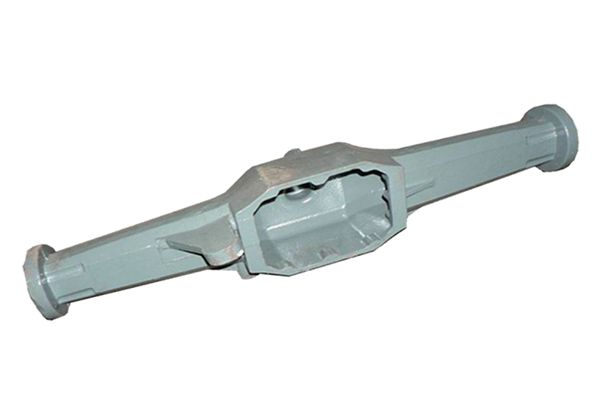

Drivetrain axle production

Forging part manufacturing

Advanced sand moulding line

Strong production capacity

Driverless tractors

The first heavy-duty combine harvester independently developed by YTO

Outdoor operation of YTO’s tractors

Product delivery

English

English Canada

Canada India

India Русский

Русский Español

Español Français

Français Deutsch

Deutsch العربية

العربية Português

Português Polski

Polski فارسی

فارسی Indonesia

Indonesia